A cheap coolant hose can be the weakest link in your car cooling system. Discover how it leads to costly engine repairs & downtime, and why a silicone coolant hose is a smart investment for vehicle reliability. In the world of vehicle maintenance and fleet management, budget pressure is a constant reality. When you’re presented with a low-price coolant hose that seems […]

Category Archives: blog

As a leading manufacturer of silicone and rubber products, we specialize in providing reliable and durable fluid transfer solutions for advanced thermal management applications. Our products are engineered to withstand extreme temperatures, pressure, and harsh environmental conditions, making them ideal for electric vehicles (EVs), energy storage systems, industrial cooling, and more. Why Choose Our Silicone […]

In the demanding world of railway systems, fluid and air transfer components must endure extreme conditions—high-speed vibrations, temperature fluctuations (-60°C to +200°C), and strict safety regulations. Silicone hoses have emerged as the go-to solution for reliable performance in locomotives, high-speed trains, and rail infrastructure. As a leading silicone hose manufacturer in China, we specialize in railway-grade hoses that […]

Silicone hoses are widely used in medical, food, automotive, and industrial applications due to their excellent flexibility, temperature resistance, and chemical stability. However, in real-world usage, hoses often endure repeated pressure fluctuations (e.g., in hydraulic systems or fuel delivery), making durability a critical factor. Pulse testing is a key method for evaluating hose longevity. This blog explains […]

In industries like industrial manufacturing, automotive, medical, and food processing, materials must perform reliably under high temperatures. High-temperature silicone hoses excel in these demanding environments, offering unmatched durability and safety. 1. Key Features of High-Temperature Silicone Hoses Made from specially formulated silicone, these hoses maintain performance even in extreme conditions: Heat Resistance: Withstands -60°C to +250°C […]

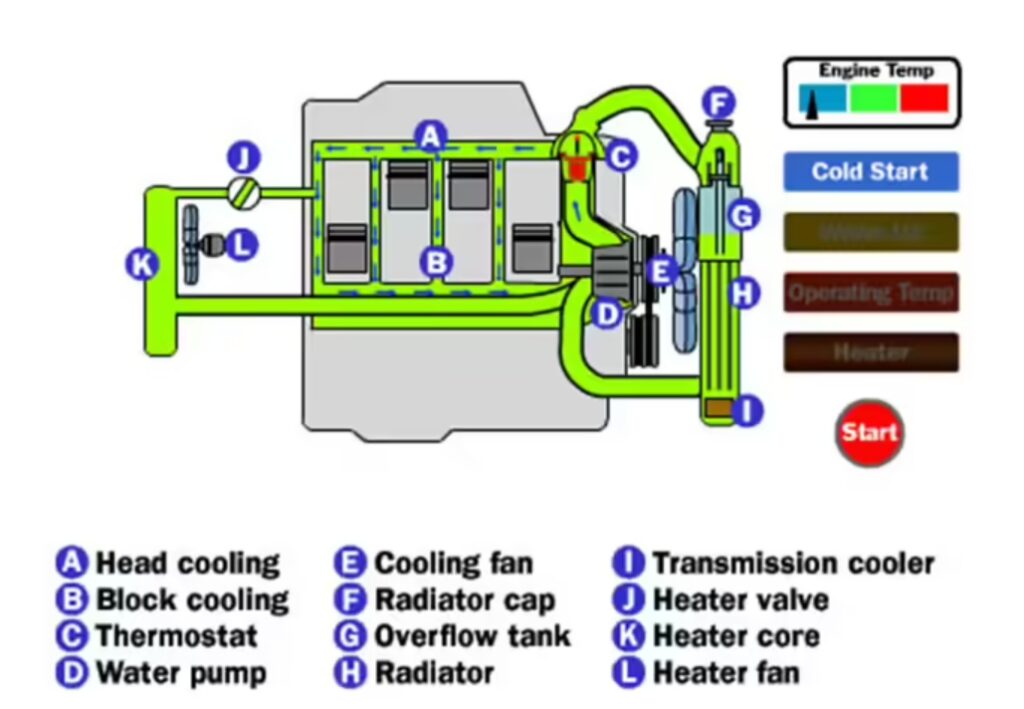

In the world of thermal management, liquid cooling has emerged as a superior solution for dissipating heat in high-performance systems. Whether it’s in electronics, automotive, or industrial machinery, liquid cooling ensures optimal temperature control, enhancing performance and longevity. At the heart of these systems lies a critical component: silicone hoses. In this blog, we’ll explore the […]

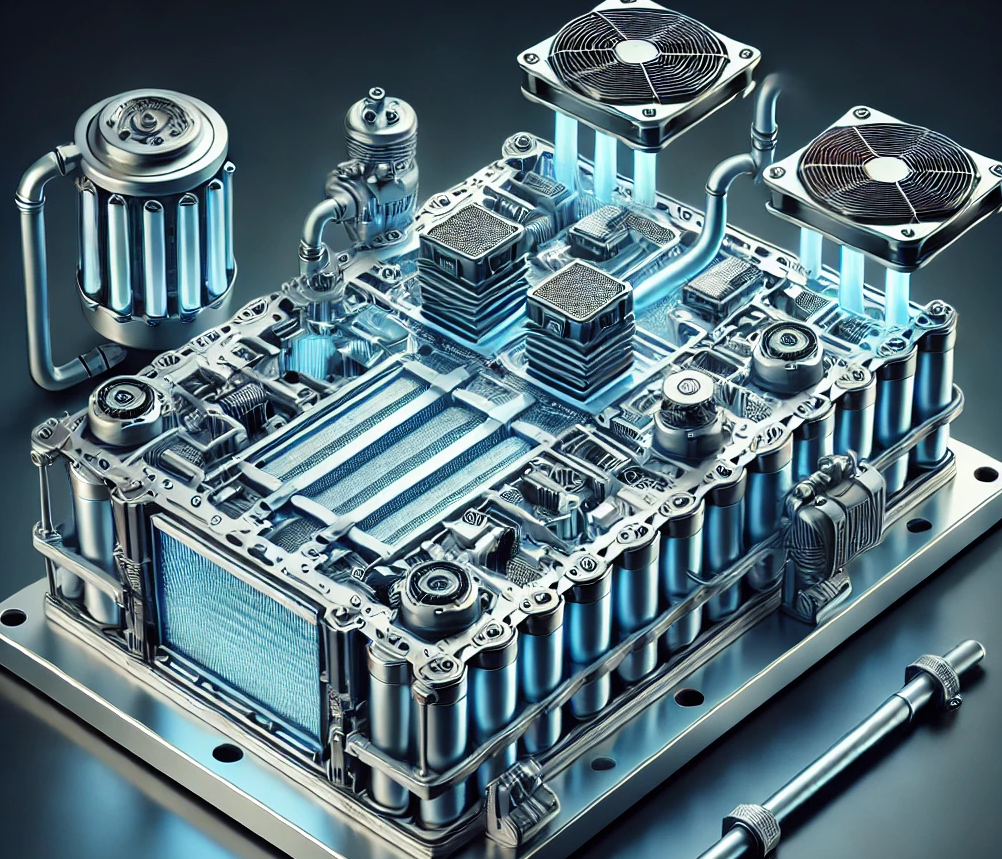

As the world accelerates toward sustainable energy solutions, the demand for silicone hoses in electric vehicles (EVs) and hydrogen energy systems is surging. Both industries are experiencing rapid growth, driving a significant need for high-performance materials that can withstand extreme conditions. In this blog, we explore why silicone hoses are becoming essential components in EV […]

At Hunt Tech, we pride ourselves on delivering top-quality silicone hoses with precision, speed, and reliability. Our commitment to innovation drives us to continually refine our manufacturing process, ensuring we meet and exceed customer expectations. One of our latest breakthroughs is the adoption of automation to streamline the production process, saving time and improving efficiency. […]

In the automotive industry, evolving carbon credit policies are transforming vehicle design and performance standards, pushing manufacturers and suppliers toward greener, more efficient solutions. For professionals in the silicone hose industry, particularly those supplying components for automotive air intake systems, this shift presents both a challenge and an opportunity to demonstrate value. The Vital Role […]

At Hunt Tech, we take pride in our attention to detail in every stage of silicone hose manufacturing. One essential technique that ensures our hand-laminated silicone hoses are durable, smooth, and built to last is our water tape wrapping process. This specialized wrapping method plays a critical role in enhancing both the surface quality and […]

- 1

- 2