In the automotive industry, evolving carbon credit policies are transforming vehicle design and performance standards, pushing manufacturers and suppliers toward greener, more efficient solutions. For professionals in the silicone hose industry, particularly those supplying components for automotive air intake systems, this shift presents both a challenge and an opportunity to demonstrate value.

The Vital Role of Silicone Hoses in Air Intake Systems

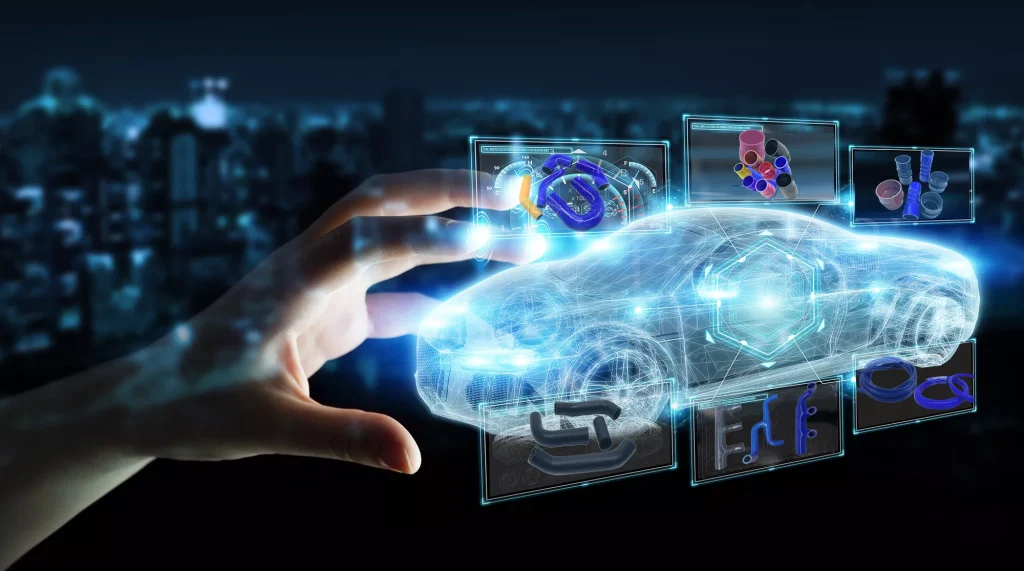

In modern vehicles, the air intake system is essential to engine performance, delivering a steady flow of cool, clean air to optimize combustion, fuel efficiency, and emissions. Silicone hoses play a critical role here:

- Sealing and Flow Optimization: High-quality silicone hoses maintain a precise, durable seal, preventing leaks that could reduce air intake efficiency. This ensures the engine receives an ideal air-to-fuel mixture, enhancing combustion and minimizing carbon emissions.

- Temperature and Pressure Resistance: Air intake systems endure high temperatures and pressures. Silicone hoses, with superior resistance to extreme conditions, withstand wear and tear, meeting environmental standards while reducing the need for replacements and waste.

- Flexibility and Vibration Dampening: Turbocharged engines produce significant vibrations. Silicone hoses provide flexibility and absorb these vibrations, stabilizing the air intake system for consistent performance that aligns with carbon reduction targets.

Future Trends: Sustainability and Innovation in Silicone Hoses

As carbon credit policies become more stringent, the focus in the silicone hose industry is on:

- Eco-Friendly Materials and Manufacturing: Developing sustainable, recyclable materials with the durability and temperature resistance of traditional silicone is a key priority. Innovations in bio-based materials can further reduce environmental impact.

- Lightweight, High-Performance Design: Manufacturers are working to make hoses lighter while retaining strength, which enhances fuel efficiency and helps vehicles meet emissions standards.

- Carbon Neutrality in Production: With greater scrutiny on the carbon footprint of each production stage, the silicone hose industry may shift toward carbon-neutral manufacturing practices, including energy-efficient factories and waste reduction, to meet low-carbon goals.

Looking Ahead: The Opportunity for Collaboration and Differentiation

The shift toward sustainability in automotive components presents silicone hose manufacturers with a unique opportunity to become essential partners in emissions reduction. By embracing greener practices and innovation, manufacturers can help the automotive sector achieve low-emission goals and play a crucial role in a more sustainable future.